Technology

MIT and ETH Zurich Develop Dual 3D Printing Method for Bones and Tendons

courtesy of technabob.com

courtesy of technabob.com

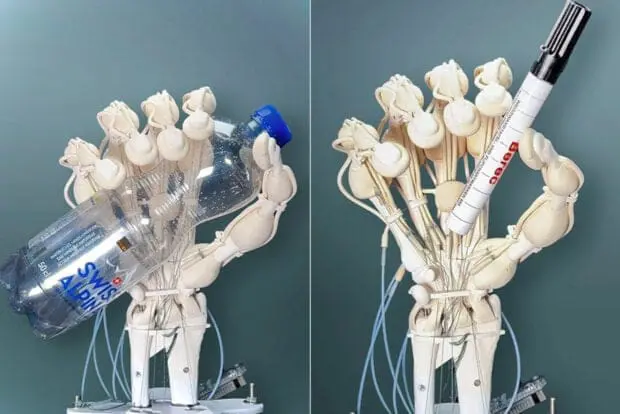

Researchers from MIT and ETH Zurich have made a groundbreaking discovery in the world of 3D printing. They have developed a method of dual 3D printing that can produce both hard elements, such as bones, and more elastic elements, like tendons, in a single printing process. This new technology has the potential to revolutionize the field of medical and industrial manufacturing.

How Does It Work?

The team of scientists at MIT and ETH Zurich have created a dual 3D printing process that combines the printing of hard and elastic materials. The bones are printed using a special resin that hardens when exposed to UV rays, while the tendons are printed using a softer elastic polymer. The printer builds up layers of each material simultaneously as the object is constructed, resulting in a seamless and integrated final product.

Endless Possibilities

The applications of this new dual 3D printing method are vast. It can be used to create not only artificial bones, but also to connect any hard elements together with flexible connectors. This means that complex structures, such as those found in the legs, neck, and gripper elements of robots, can be created in a single printing process. The possibilities for the future of 3D printing are truly limitless.

A Game-Changer in Manufacturing

This new technology has the potential to revolutionize the world of manufacturing. Traditional methods of creating complex structures with different materials are often time-consuming and require multiple steps. With this dual 3D printing method, the entire process can be streamlined into a single step, saving time and resources. It also opens up new possibilities for customization and personalization, as objects can be tailored to individual needs and specifications.

The future of 3D printing is closer than ever before, thanks to the groundbreaking work of researchers from MIT and ETH Zurich. With their dual 3D printing method, the production of complex structures with both hard and elastic elements has become a reality. This has the potential to change the way we manufacture objects, from artificial bones to robotic components. The possibilities are endless, and the future is bright.

Hello! I’m Roger Jenkins, your go-to source at ReportingTheNews.com. I’m a USC graduate who combines journalistic precision with a Trojan’s passion. Based in sunny Los Angeles, my days are filled with more than just sunshine; they’re about capturing stories that resonate.

Beyond the newsroom, I’m an avid triathlete. Swimming, cycling, and running are more than just sports to me; they embody my commitment to discipline, focus, and a healthy dose of competition.

My love for travel takes me far and wide. Guadalajara, with its vibrant culture and unforgettable tacos, has a special place in my heart. I’m always searching for the next great story or a hidden culinary treasure.

At home, Nala, my energetic pet, is my constant companion. Together, we’re known in our neighborhood for our morning runs and evening strolls.

I’m driven by a belief in the power of storytelling to unite communities. Join me as we explore impactful narratives and stay updated with the latest news. You’ll also get a peek into my sports passions and travel escapades.

Want to get in touch? Follow me on Instagram for more insights and updates.